In their own words: Our 2016 WHSAD Interns

/WHSAD 2016 Interns (from left to right): Jose, Cesar, Christopher, DeVere, and Christie.

Great to see teak woodwork go from grey to gold!

Great to see youth learn to do it! Below this intro, Christopher, Christie, Cesar, Devere and Jose describe their summer, in their own words, with photos they selected.

PortSide is psyched to be growing our CTE summer preservation internship program! Last summer we had three interns, this summer five. CTE stands for Career and Technical Education, what was once called vocational education. We are partnering with the fantastic preservation-themed Williamsburg High School for Architecture and Design (WHSAD). That’s a Title 1 school with a high graduation rate. This program is supported by the NYC Department of Education which pays the students, and by ConEd which supported costs on our end.

This summer’s project was a big one!

Restore the wheelhouse teak windows and doors that were badly weathered, and suffering from poor repairs in prior years. We removed them to do a quality job.

The interns learned how to take wasted, weathered grey wood and make it gleam. We gave them management experience by having one be "lead intern" each week. The historic ship MARY A. WHALEN got a major boost, improving an asset on the National Register, and a ship regularly open to the community of Red Hook and world beyond.

A challenge was not having a woodshop inside a building, a space that would shield interns from the heat, a place where project pieces and tools could be left out over night. Every day, the gang had to bring out and set up windows and doors and then put them back in storage. Despite that, the interns got a TREMENDOUS amount done. The revarnishing work will go on over the winter into next year.

We also gave the interns practice in modern marketing by having them write the text below and select the photos for their story.

Boating!

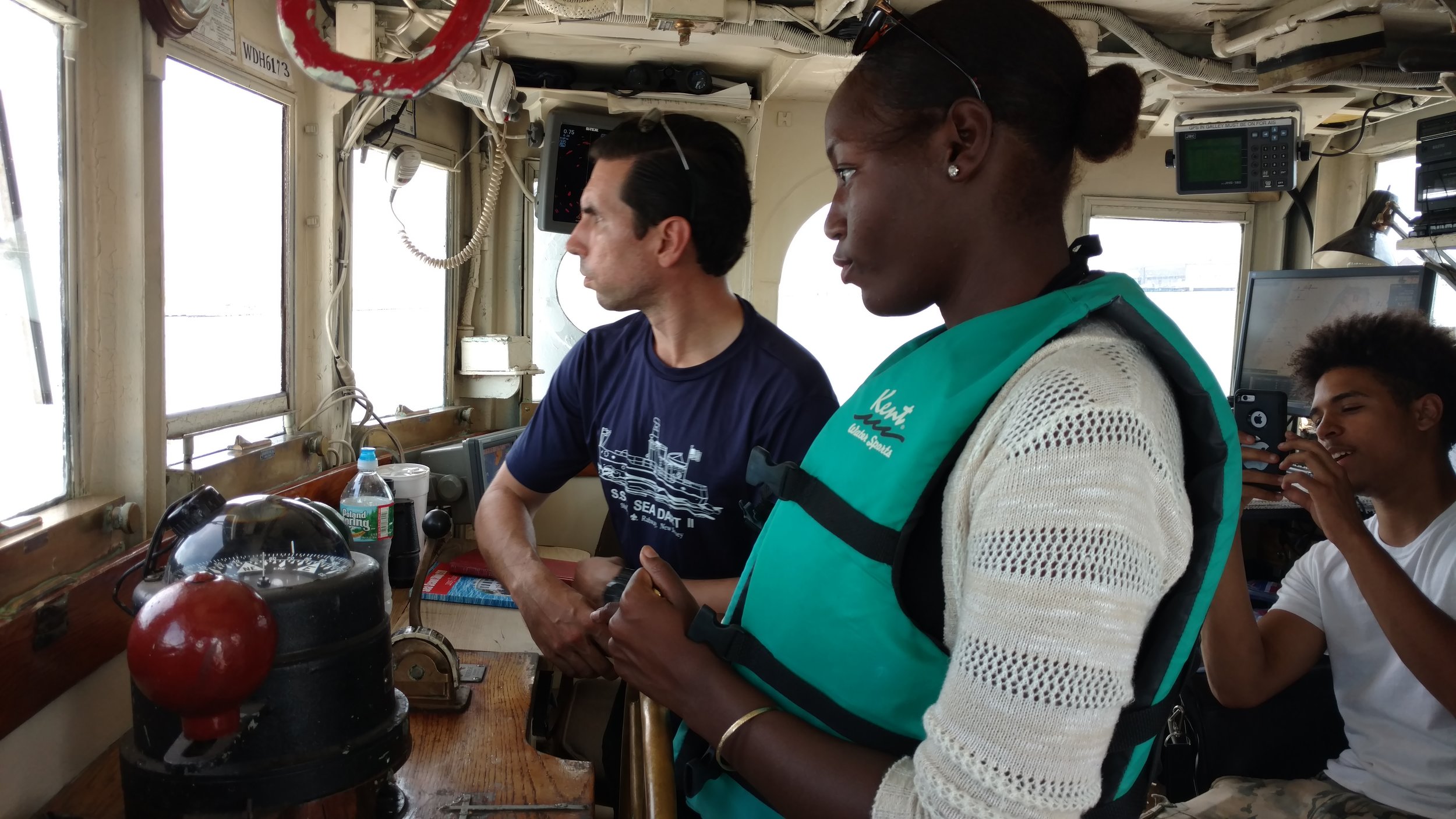

Interns also got experience in our rowboat and kayak, and a harbor tour on the SeaScout boat Sea Dart II which our interns got to steer! Thanks, Capt. Jimmy Zatwarnicki for that! The whole summer was about boats and several of them had never been on a boat before. Supervising was a team effort, with Richard Evans, Peter Rothenberg, Carolina Salguero and John Weaver offering different skills under different situations.

Intern Christie, who is Haitian American, contributed to our Red Hook WaterStories project by reporting on a company that exports used vehicles to Haiti. She was interviewed in Creole and in English andwrote a text in English explaining how the Red Hook Shipping Company ships out of the Red Hook Container Terminal. Getting into the port was a special experience for her.

Thank you WHSAD, DOE, RHCT, Sea Dart II and ConEd!

Lunch time in the galley

Christopher

My time here at PortSide has been interesting. I walked in with no prior knowledge of sanding, scraping and restoration. We practiced scraping on some weathered wood and that gave us the skills we needed to work on the historic wood on the MARY WHALEN. We were given a good amount of time for our lunch break and were sometimes even offered food if we didn’t bring any. We were treated with respect and not talked down upon.

We took the windows out of the slots and scraped, sanded, and varnished them. We did the same to the door but without the varnish. After that we sanded the railing and varnished it. It was extremely hot during this internship but we were given a cool place to rest in the “galley” - the kitchen. Carolina bought us insulated water bottles so we can have cold water and shared the fridge with us. She always held out a helping hand to me whenever I needed it.

This was my first boat experience, and I’m impressed on how much I learned in these six weeks. I learned how to coil rope, and how to make extremely tight knots. This internship was very organized which I learned very quickly. In conclusion, I’ve enjoyed my time as an intern for PortSide and recommend it for other young interns looking for a new experience.

Christie

Six weeks at PortSide was a learning experience. I was able to learn many things, not just work skills but also about boats and all that happens on the water. In my first week I learned the basics of a boat. On a boat all the terms are different from the ones we are used to. In our first week we created our work space on the pier and begin with sanding the paint off the top skylights. We learned about the different types of sanding paper. We then moved on to learning how to scrape and sand on practice wood pieces. While we were working on learning the techniques to restoring wood, Richard was working on getting the windows, doors, and vertical pieces out of the wheel house. To assist us in safely getting the windows and doors onto the pier we created a box to send them down in. We created it from an old pallet. Once we got all the wood pieces from the wheelhouse onto our workstation we began restoring them.

Wheel house window, labeled and ready to be removed.

The process was a long and tedious one. A majority of our time was spent on making sure everything was completely ready for varnish. The varnish would ensure that the windows would not be weathered again and can remain in good shape. We were given a varnish lesson. Varnishing is a detail oriented process. We need six coats of varnish on each and had to sand with fine sandpaper in-between each coat.

Sanding the wood

Applying varnish

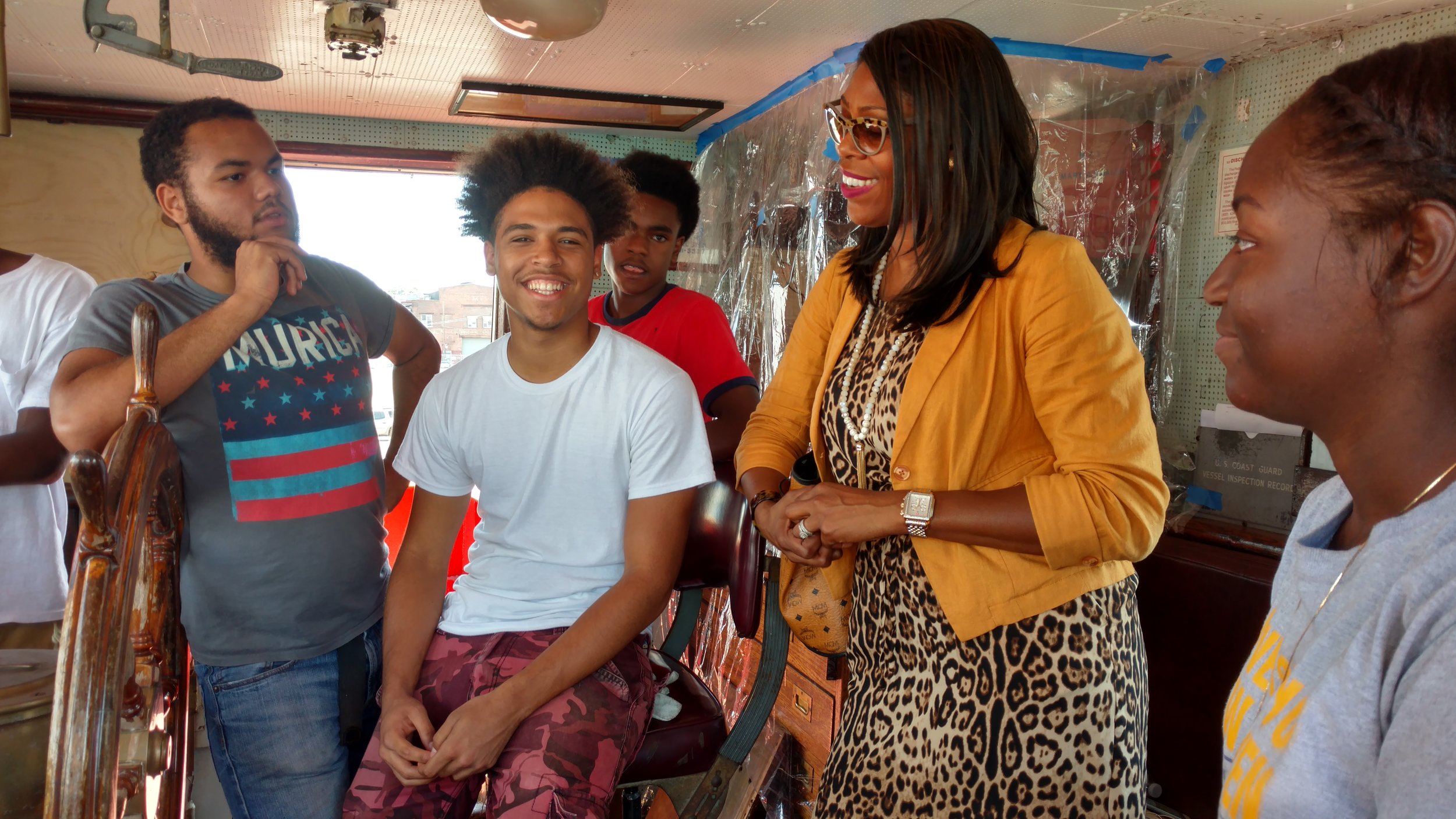

Not only did we work on the window, we were able to show others who came aboard the boat the work we were doing. In our fifth week Red Hook Initiative came with some youth from the area. We gave them a tour of the boat and the progress we made in our work. We also had a visit from Johari Jenkins from Con Edison. She was already familiar with the boat but not with the project we had been working on.

One of my favorite experiences during my time was being able to take a boat ride in the Sea Dart 2. We went along Red Hook and near the Statue of Liberty. We also were able to go kayaking in the water next to the MARY A. WHALEN

Kayaking

Overall my time at PortSide has taught many valuable skills that I can always apply later in my life. I’m satisfied with the amount of things I’ve learned and the outcome of our work. The major difference in the wood was extraordinary and our hard work paid off.

Cesar

Hello my name is Cesar Martinez. I am one the interns who was recruited to help out around the ship. (Within the picture I am the one who has the “spin out” t-shirt)

My Experience

Working within PortSide was a great and a new experience for me. This was my first job I had got in my life, and it was great. I have learned many things that I will take from this job. For one, I have gained new experience on how to care for wood. Also, a little bit of sailor talk. That, I will still use after am done with this job. I thank all the staff of PortSide for giving a great experience and showing me something that I thought I would never learn about.

(These were three of the five windows we worked on)

The BIG Project (also side project)

The 6 week project was restoring the exterior windows of the wheelhouse; there were five of them. The first week or two were actually getting them out of their places and bringing them down safely by a pulley system that one of the workers had created for this part.

(This photo is the interns and Richard, the one who created the lowering system)

(Before we had started working on the door)

Within the third week our advisers taught us have to scrape the wood and sand it down to a smooth new texture, which was a light brown color. The fourth week they checked our work to see if we had completed the transformation of the nasty dirty wood into its best smooth version.

(After some work we had done on it)

Also in the fourth week they had taught us about varnishing and how to do it, which was my first experience with it. Between the last two weeks we had to repeat and rinse to build the coating on the wood.

We gave a tour of the ship to young teenagers who were from the non-profit organization, Red Hook Initiative

(Touring the wheel house)

In week five a very special person came to the ship to see what we are doing as interns. Her name was Johari Jenkins. She was from Con Ed and wanted to know what we were doing and how this will help us after we are done. She was very into how what we want to do as a career and how she can help us.

(Johari is the women wearing the yellow jacket)

Within the last week we went on a boat called the Sea Dart II, which took us on a tour of the Red Hook area, which was nice.

My Thanks

I will like to thank PortSide for giving me an experience that I hadn't had, and for all the experience the staff gave me about the field they work in. Also it was a great time that I will never take back.

Jose

In the beginning of time there were these interns they started scraping paint the first day of work and that actually gave us a sense of what he internship would turn out to be. Our main job was to restore the old wood from the wheel house of the ship by scraping all the old varnish off the wood, then sanding it off to make it smooth like if it were new wood. We had scraping and sanding classes before starting onto the real woodwork of the ship. Before we actually started sanding and scraping the wood, we needed a plan on how to remember which windows went where. We were labeling them, same goes with the nails.

Taking careful notes

We created a large box big enough to fit one window at a time inside. After that has been done we created way to pull down the window from the top of the wheel house down on to the bottom deck. This activity required the help of all interns plus one of our supervisors. After all windows where down they were moved on to tables we set up off of the ship. That was when we started our first real scraping job on the windows, after all the old varnish was off we started sanding the wood making it smooth enough to add new varnish. We haven’t completely finished varnishing the windows with all coats but after it is done, they will go back up in to the wheel house.

My Opinion

Working at PortSide did not only help me make money, but it actually gave me enough experience with woodworking to enhance my resume for the future. My time and moments at PortSide was the best, I had lots of fun with my interns and the work itself wasn’t really that bad. I enjoy working hands on, it keeps it active instead of working on a computer all day. I hope to return and see my fellow supervisors once again.

DeVere

Hello, I’m an intern for Port Side New York, a non-profit organization based in Red Hook, aimed at creating better urban waterways. Our job here was to help around as much as we possibly could.

My name is DeVere. I am the second person from the right in the photo up top. I worked with 4 other interns as a team to get as much done to restore this ship as we could.

The job started out with a basic orientation. We were given a tour of the ship, shown what the organization does, and treated just like guest. But it wouldn’t be a job if it was all play and no work. Our first few days on the job started out with us preparing our small site for where we would do most of our work. Even in these few days, I learned quite a few things.

Working on a boat was truly a brand new experience. Having never been on a boat for more than a few minutes prior to this, I had to get used to things like the motion/swaying of the boat. It even lasted with me after I got home.

Later into our internship, we proceeded to do a fair bit of woodworking. Luckily, for some of us, having taken an Architectural Preservation class, our knowledge of woodworking managed to carry over on to our internship. This helped a little, but there was still much we didn’t have a clue how to do, and that’s where the supervisors came in.

But aside from that, one of the most beneficial lessons we learned from this internship were the ones on how to work as a team. And while we were never sat down to talk about this, naturally we began to find ourselves cooperating better as the internship went on.

We received guidance from people like Carolina, Peter, Richard, and a few more. They taught us a lot about the skills we used to complete our job.

Our job was primarily to restore some wooden frames from the windows in the wheel house. This was primarily what we spent 80% of our time doing. At times it could be a bit tedious, but through determination we managed to get the majority of our task done. This task was separated into three phases. None of which were exactly easy to do. The windows were taken down from the wheel house: a room at the very top of the ship. This brought up the issue of getting it down in one piece. Eventually we came up with the system of using a rope to lower it to two people on the deck. We repeated this system about 4 more times to get all of the windows down.

After that phase was done we proceeded to sand them down. The windows were extremely old, so we had to work on getting out many of the imperfections that accumulated overtime.

We started with a lower grit sandpaper, and worked our way up till we got to a fine grit. At this point we all felt a sense of satisfaction as we were able to move our hand over the wood and have it feel smooth.

Final stage of all of this was the varnishing. This one was a bit tricky and required a bit of extra guidance from Richard and Carolina. Quite a few errors were made and had to be fixed, but in the end we finally got a grasp of what it was we were doing.