Richard's Blog

/wheelhouse woodwork Restoration on the tanker Mary A. Whalen: The Richard W. Evans Story

June 4, 2016

Went for a bike ride along the waterfront in Red Hook. I ventured as far as I could on each dock, pier or wharf until it ran out or a guard ran me out. Saw plenty of ships,boats, barges and a few sunken wrecks.

Eventually I arrived at the Atlantic Basin, near the Brooklyn cruise ship terminal. There I saw two posters from PortSide NewYork. The first was “Tanker Opera”, two of my favorite subjects – ships and opera. The other was an invitation to “Get Involved – Volunteer”. I took pictures to be sure I got the contact information correctly.

As soon as I got home, I whipped together a resume of maritime related experience and sent it off to PortSide. Within a few days I met Carolina Salguero,the President and Founder aboard the Mary A. Whalen. After a tour of the ship, we talked about the tasks and challenges ahead. I admit being a little nervous, anxious that my qualifications would meet the needs of PortSide New York. Fortunately, I was invited to join the project.

Balance of June, 2016

Over the next couple of weeks, I spent a lot of time with John Weaver (production coordinator and maintenance guru) and Peter Rothenberg (historian). I learned a lot about the Mary A Whalen and her issues. We discussed many of the projects underway and planned.

We reinstalled the bridge-deck railings that had been removed and refinished. We tried to come up with a plan on how to work about 10 feet off the deck on the aft windows of the pilot-house that had been painted shut and desperately needed maintenance (the jury is still out on that one).

I took pictures of items needing repair or replacement like the companionway door and the captain’s cabin door.

July 7 et seq

After considerable examination and rumination, I figured out how to remove the sashes from the wheel-house. This was necessary because we needed to remove the old varnish,make repairs and refinish the sashes and the trim around them.

The trick was to drill out the bungs (wooden plugs covering the mounting screws) in the window frames, remove the screws, remove the rails and ‘simply’ lift out the sashes.The first one was deceptively easy and the screw came out without incident.

Now overconfident, I started to drill the second bung. After wood, I ran into two different types of epoxy and finally the bronze screw. Somebody had removed these rails before – epoxy would not have been used to mount bungs or cover screw heads in 1938. The drill damaged the screw slot and I had to drill out the screw to remove it.

Each screw and bung seemed to present new problems. In some cases, there was no screw, only epoxy and the wood plug. In another, the screw had previously been broken off in the steel behind it.

Time was getting critical because we had a group of five interns coming from the Williamsburg HS for Architecture and Design help us with the scraping, sanding and varnishing work. Over then next three days I got all of the rails removed and then it was not difficult to remove the sashes. With the interns help, we carefully lowered each valuable sash down to the main deck in a container made from a shipping pallet and some Styrofoam and ropes.

The interns -Christopher Bruns, Christie Dorestant, Cesar Martinez, Jose Santos and Devere Walcott - then started their on-the-job-training on the rails and four of the five sashes, learning new skills and tools while scraping, sanding and varnishing.

One of the sashes had obviously caused problems over the years and had been inexpertly repaired several times. When we got the ship, the last repair was to simply screw down a couple of steel brackets inside and outside.

With the brackets removed, the corner joint opened up easily to reveal the effects of prior repairs. The first was to drive a couple of finishing nails through the mortise and tenon joint. Next, holes were drilled through the stile (vertical piece) into the rail (horizontal piece), softwood dowels were inserted, maybe with some glue, and the holes capped with teak bungs. The next ‘fix’ was to drive a long bronze screw through the mortise and tenon. The fourth and final attempt was the angle brackets.

With the joint open, I found the softwood dowels had rotted out completely, leaving only a little black residue. The nails and drilling for dowels and then the wood screw chewed up the tenon, leaving only a small stub. For a repair, I cleaned out the rotten pieces and soaked the area in fungicide. Then, I inserted a piece of teak to fill the cavity where the tenon once resided. After that, I drilled new holes and inserted teak dowels to support the joint. Finally, I clamped the sash vertically and used putty to fill every hole I could find and poured thickened epoxy into the open cavity, hopefully filling and gluing everything together.

With the interns busily working on the sashes and vertical window frame parts, I had to remove the last remaining piece – the window-sill that ran under all three of the forward facing windows. There was no obvious way that it was attached, but it was solidly in place. Finally I found that there were screws down inside the window box going through the steel bulkhead, holding the sill in place. I still don’t know how they drilled the steel down there and attached the sill. I had to use a right-angled screwdriver and a lot of patience to get those screws out. When it was finally removed, I found that it had been removed before because there were at least two or three sets of screw holes in the bulkhead and in the window sill.

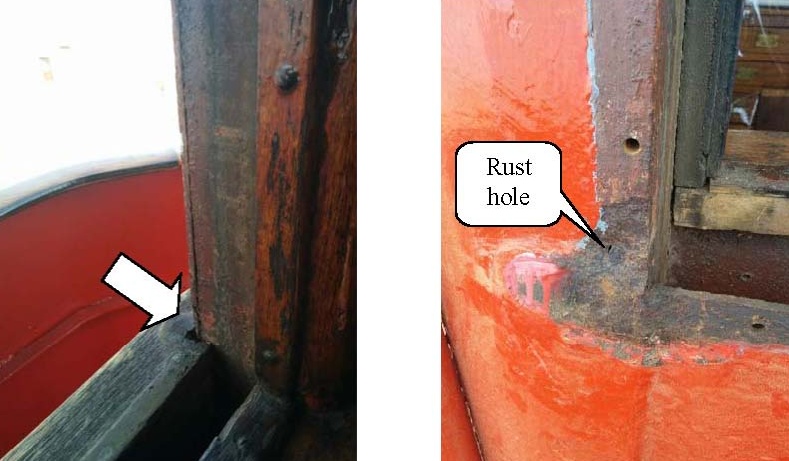

Even before removing the window-sill, we were concerned that the starboard end did not actually touch the bulkhead – there was an unexplained gap. After the sill was removed, we could see the bulging and buildup of rust that prevented alignment between the sill and the bulkhead. The rust had actually eaten through the bulkhead.

August 16, 2016

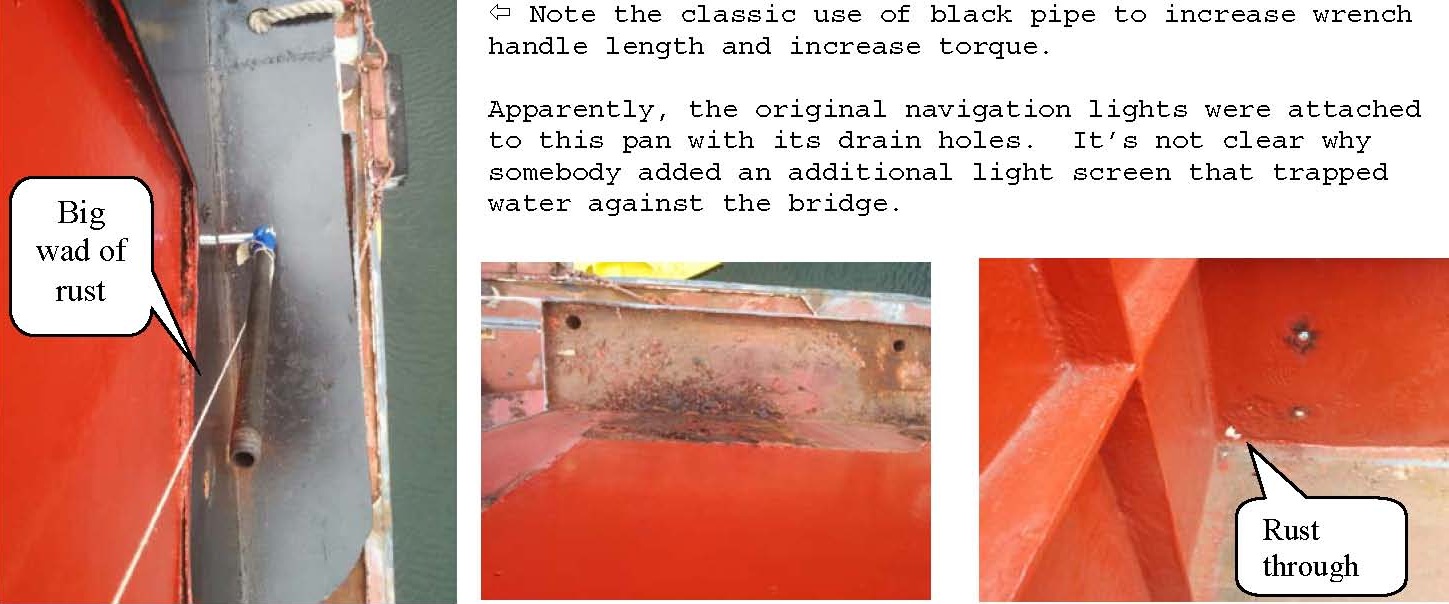

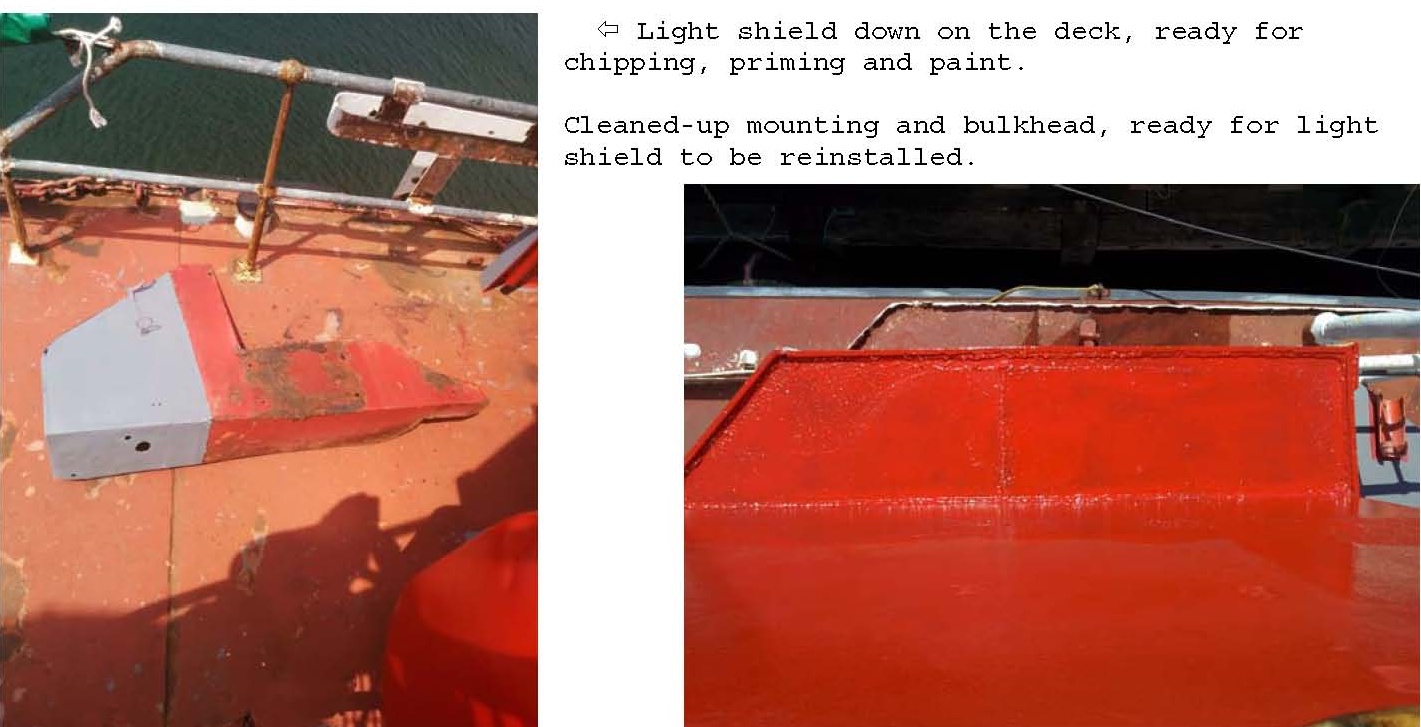

The crew from DC9 painters union and our friend Arsenio have been working on the superstructure, and the Mary Whalen is looking pretty sharp. She has navigation light screens (mountings that make the lights visible only from certain angles) that must be painted flat black. They have been painted in position but it is obvious that there is rust between the screens and the bridge structure. Using a torch to burn the paint and rust off of the mounting bolts, Peter and I were able to remove the port and starboard screens and lower them to the boat deck. There, the layers of rust were chipped away and both the screens and the bridge were primed and painted. They should look really sharp when reinstalled.

August 24, 2016

The pilot-house doors need a little refurbishment. All of the outside varnish has weathered away and the teak shows damage from the elements, particularly raised grain and shrinkage.

The teak panels have shrunken and can be moved from side to side. No amount of varnish will make this weatherproof. By cleaning old varnish and other detritus out from between the panels, the panels were pushed closer together and a thin piece of teak was shaped and inserted to take up the extra spacing.

During restoration, the 1/4” plate glass in one of the doors was accidentally broken. The molding holding the glass in place was removed from both doors, revealing some very moldy caulking. This material was originally a light gray color!

Taking measurements for the new glass showed that the window opening wasn’t rectangular. While the top and bottom, left and right sides were identical; the diagonal measurements were off by 1” - the glass was actually a parallelogram. It turns out that all doors running fore-and-aft on the Mary Whalen are parallelograms with the horizontal sections parallel to the ships shear, not to the horizon.

Not only that, the ‘glass’ on the other door was actually Lexan. Now we have to decide whether to repair the broken window with glass or Lexan. The decision affects which caulking/adhesive we select.

Sept 6, 2016

While waiting to select and order the material and caulking for the door windows, I started stripping old varnish from the interior of the wheel-house.

The sill of the starboard wheelhouse door frame was broken at some time in the past. It looks like the forward end of the sill or the adjacent bulkhead was hit by something very strong or heavy. The forward edge of the sill is pushed inboard between 1/4" and 1/2”, splitting the wood and pushing in the interior wall panels. The after end of the door-sill is only slightly displaced.

Someone had worked on the aft edge of the sill, using epoxy and wedges to try and make the door close evenly.

Just forward of the impacted starboard door sill, the window box is rusted through and the wall paneling between the door and the window box has been broken and pushed inward.

On the port-side, there was no door-sill when PortSide acquired the Mary Whalen. A temporary sill was fabricated to keep some of the weather out. Unfortunately this was too little, too late. The two-by-four beams that support the door frames were rotted away by the rain-water that got in under the doorway over the years. That is going to be some tricky repair job to make the supports secure again.

Both doors had some aluminum extrusion and neoprene weather-stripping installed in the recent past to replace the original felt weather stripping. On the port side door, there was some home-brew material installed that looked like a bad fungal infection where the neoprene should have been. Its rough surface would not have provided any kind of seal.

The forward side of the port doorway had no weather-stripping installed. From the array of holes in the frame, it appears that felt was used several times to seal the doorway but there is no sign of screw holes that would have been used to attach the aluminum extrusion.

This installment of Richard's work diary end's here, but the project, his adventures and painstakingly achieved successes continue.

Since September, Richard has erected a scaffolding up to the rear of the wheel house, stripped and restored the two stern facing windows - learning, to his consternation, that there is nothing square about MARY. But that is a story for another blog post.